5 ways hidden air leaks wreak havoc on equipment

Beyond performance issues and reduced energy efficiency, the damage caused by unnoticed gas or compressed air leaks can be substantial. Here are some of the top issues that can be averted with the Fluke ii900 Acoustic Imager, which will help you find these sneaky leaks so you can repair them before they cause costly downtime.

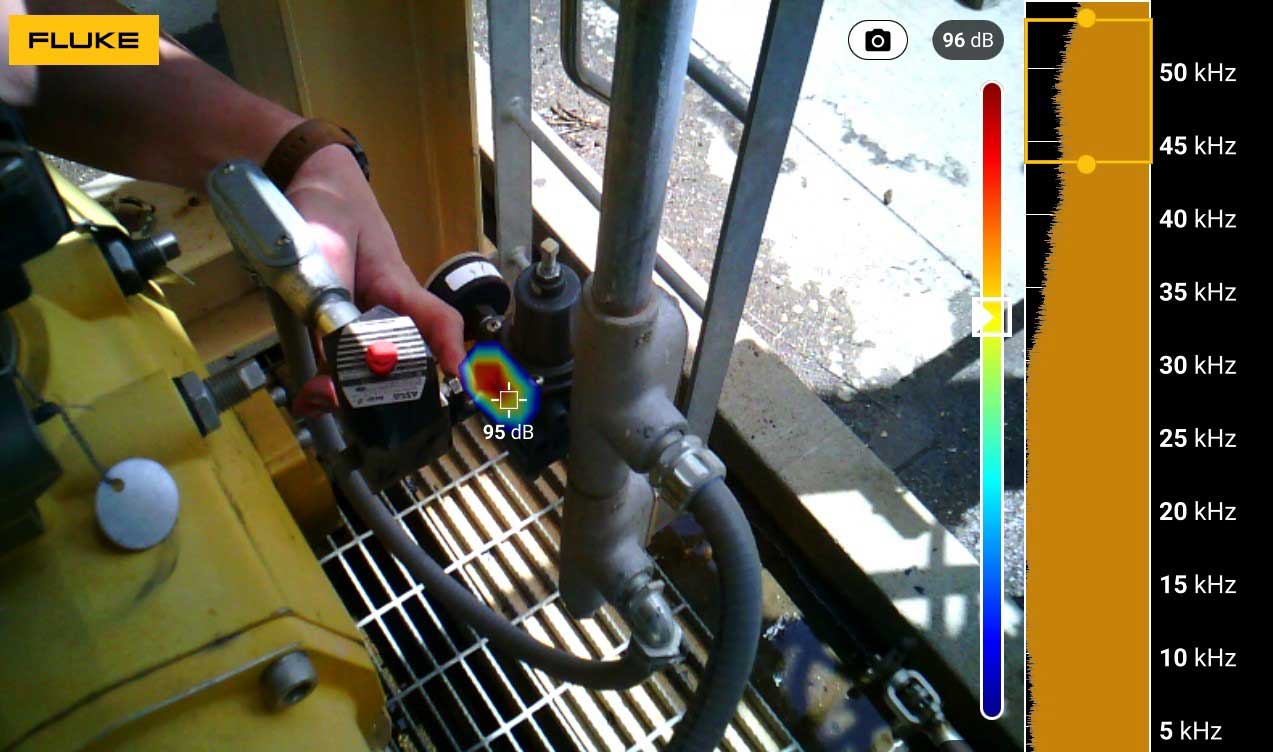

1. Control Air Pressure Regulator Failure

Image courtesy of ADG Concepts

Designed to maintain internal component dryness, the air pressure regulator initially led the customer to believe the sounds were typical venting. However, upon using the Fluke ii900 to visualize the sound, it revealed two leaks, indicating abnormal venting due to failed seals leading to air leakage.

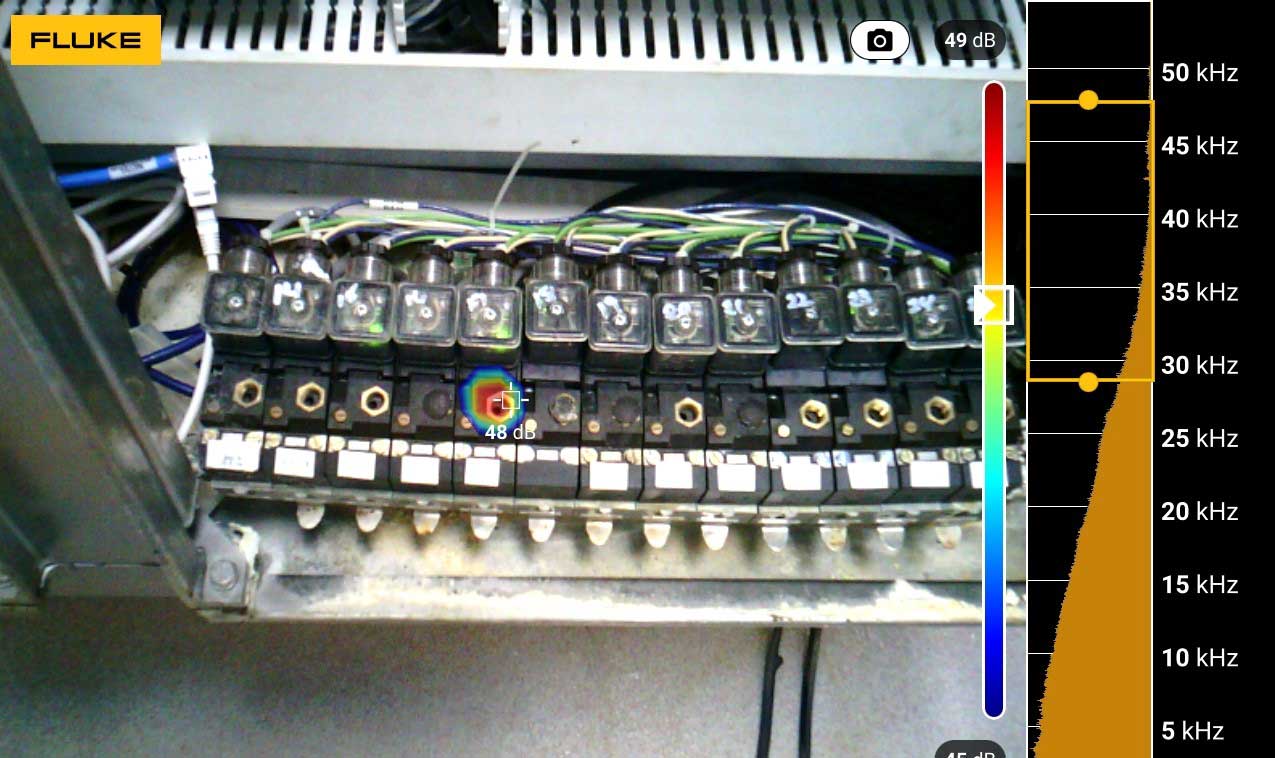

2. Process Control Valve Panel Condensation

Designed for an electric and pneumatic process valve, this control panel was the focus of a customer complaint about an apparent electrical failure. However, the true culprit, as revealed by the Fluke ii900, was an inefficiently operating compressed air dryer. This led to condensation in the vicinity, ultimately resulting in the failure of the electrical components.

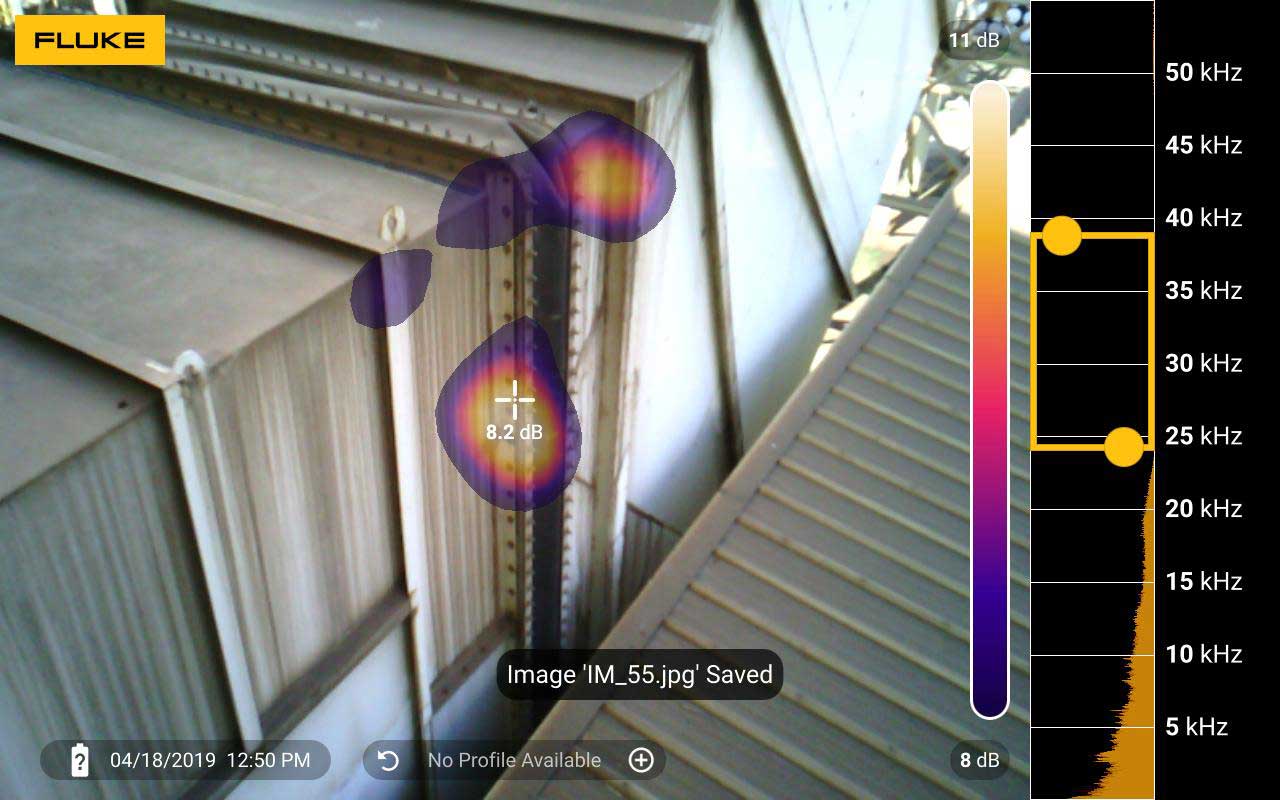

3. HVAC Ductwork Leaks Introduce Failure Opportunities

Insufficient pressure or vacuum in HVAC ducting can result in contamination, equipment malfunctions, or environmental safety concerns if not adequately vented.

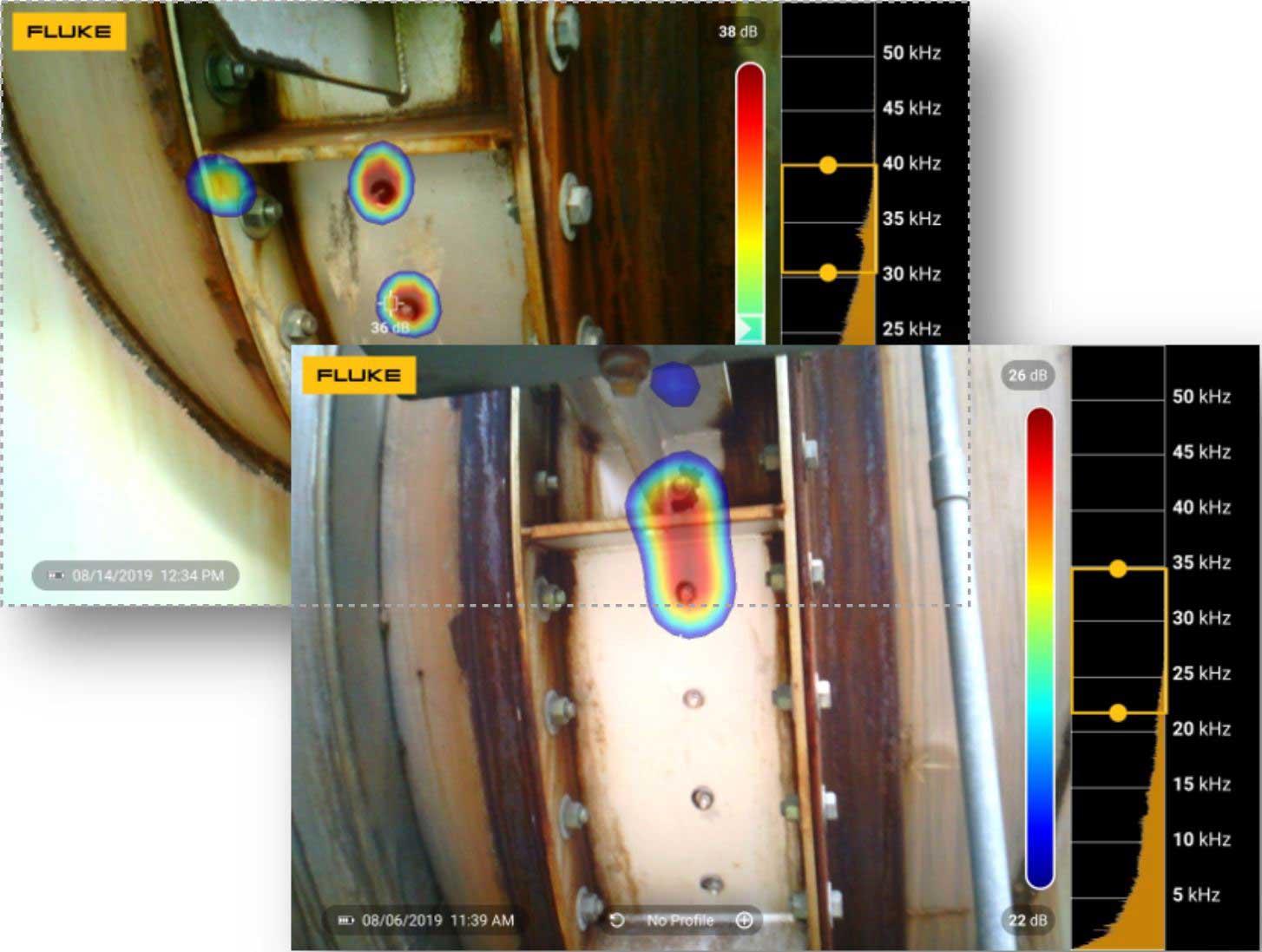

4. Air Handler Ducting Leaks in Gaskets and Fasteners

In the ducting system of a paint booth, numerous leaks have been identified due to faulty gaskets and loose or completely missing fasteners. These leaks pose a risk of plant shutdown or environmental discharge. It's noteworthy that maintenance was conducted on this equipment just the week before, yet the leaks went unnoticed.

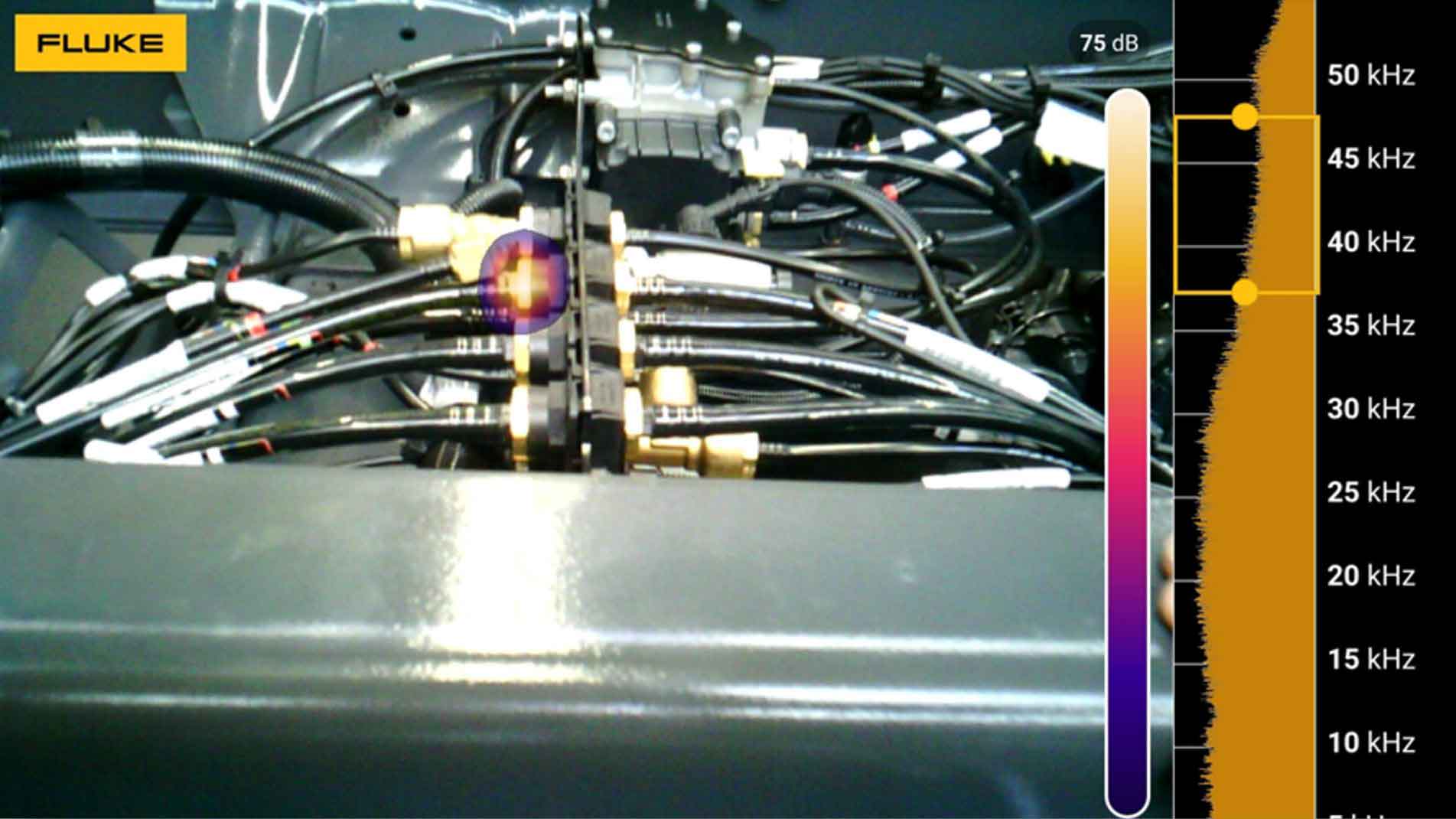

5. Automotive Air Line Leaks Reduce Performance

These pneumatic air lines belong to a semi-truck. Leaks within pneumatic systems represent a quality defect that can affect the functionality of onboard systems. Traditional leak detection methods are highly time-consuming in such scenarios and are prone to overlooking these specific types of leaks.